Principio de funcionamiento del concentrador de oxígeno

Compartir

I. Portada

- Título: Explicación detallada del principio de funcionamiento del concentrador de oxígeno RespirEasy

- Subtítulo: El mecanismo de conversión del aire al oxígeno

- Orador: RespirEasy

- Fecha: 25 de agosto de 2025

II. Índice de contenidos

1. Funciones principales y escenarios de aplicación del concentrador de oxígeno RespirEasy

2. Clasificación de las principales tecnologías de concentración de oxígeno

3. Análisis de los principios básicos de funcionamiento de diversas tecnologías

4. Componentes clave y sus funciones

5. Precauciones para el uso del concentrador de oxígeno RespirEasy

6. Resumen y preguntas frecuentes

III. Funciones principales y escenarios de aplicación del concentrador de oxígeno RespirEasy

- Función principal: separa el oxígeno del aire y proporciona una fuente de oxígeno de alta concentración (normalmente entre el 90 % y el 96 %).

- Escenarios de aplicación

- Médica: oxigenoterapia domiciliaria, atención de urgencias hospitalarias y tratamiento complementario para enfermedades crónicas (por ejemplo, EPOC)

- Industrial: Corte de metales, soporte de combustión por reacción química.

- Escenarios especiales: Suministro de oxígeno a gran altitud, operaciones de buceo

IV. Clasificación de las principales tecnologías de generación de oxígeno

1. Adsorción por oscilación de presión (PSA) mediante tamiz molecular: la tecnología principal para concentradores de oxígeno médico domésticos y de tamaño pequeño a mediano.

2. Separación por membrana: adecuada para aplicaciones de baja concentración y bajo flujo (como la producción de oxígeno montada en vehículos)

3. Electrólisis del agua: se utiliza principalmente en aplicaciones industriales o para escenarios especializados de demanda de oxígeno de alta pureza.

V. Principios básicos de funcionamiento de diversas tecnologías

(I) Adsorción por oscilación de presión (PSA) mediante tamiz molecular

1. Principio básico: Utilizando la capacidad de adsorción diferencial de los tamices moleculares para nitrógeno y oxígeno, el oxígeno se produce a través de un ciclo de adsorción presurizada y desorción por descompresión.

2. Flujo de trabajo

- Fase de Presurización: El aire filtrado ingresa a la torre de adsorción, donde el tamiz molecular adsorbe el nitrógeno y el oxígeno pasa a través de él y es recolectado.

- Fase de Descompresión: Se despresuriza la torre de adsorción y el tamiz molecular libera el nitrógeno adsorbido, restableciendo su capacidad de adsorción.

- Alternancia de doble torre: Dos torres de adsorción presurizan y despresurizan alternativamente para lograr una producción continua de oxígeno.

(II) Método de separación por membrana

1. Principio básico: utiliza la permeabilidad diferencial de las membranas de polímero para el oxígeno y el nitrógeno, permitiendo que el oxígeno pase a través de la membrana de forma preferencial.

2. Proceso: El aire comprimido ingresa al módulo de membrana, donde el oxígeno se filtra rápidamente al otro lado, mientras que el nitrógeno queda atrapado y descargado, dando como resultado una baja concentración de oxígeno (aproximadamente 30%-50%).

(III) Método de electrólisis del agua

1. Principio básico: El agua (H₂O) se descompone mediante electrólisis, produciendo oxígeno e hidrógeno en los electrodos.

2. Proceso: Se inyecta agua con electrolito en la celda electrolítica. Al suministrar energía, se produce oxígeno en el ánodo (para su recolección y uso) e hidrógeno en el cátodo (para una descarga o recuperación segura).

VI. Componentes clave y sus funciones

- Compresor de aire: proporciona aire presurizado para impulsar el proceso de adsorción/permeación.

- Tamiz molecular/membrana de separación: Elemento de separación central, que consigue la separación de oxígeno y nitrógeno.

Sistema de filtración: Incluye almohadillas filtrantes primarias y filtros de alta eficiencia para eliminar el polvo y las impurezas del aire. Sensor de concentración de oxígeno: Monitorea la concentración de oxígeno en tiempo real para garantizar el cumplimiento de las normas.

- Tanque de almacenamiento de oxígeno: almacena el oxígeno generado y estabiliza la presión de salida de oxígeno y el caudal.

VII. Precauciones para el uso del concentrador de oxígeno

- Requisitos ambientales: Evitar altas temperaturas, humedad y ambientes polvorientos y garantizar una buena ventilación.

- Mantenimiento regular: reemplace los filtros y tamices moleculares (modelos PSA) según lo programado para prolongar la vida útil del dispositivo.

Normas de seguridad: Mantener alejado de fuentes de fuego (el oxígeno favorece la combustión). Los modelos de electrólisis requieren atención a la seguridad de las emisiones de hidrógeno.

- Control de flujo: optimice el caudal de salida de oxígeno según las necesidades médicas o los requisitos de la aplicación.

VIII. Resumen y preguntas frecuentes

- Resumen: Comparación de escenarios aplicables y principios básicos de diferentes tecnologías de generación de oxígeno.

- Preguntas frecuentes

¿Por qué se utilizan frecuentemente las tecnologías PSA en concentradores de oxígeno domésticos? (Respuesta: Bajo costo, alta concentración, tamaño pequeño y apto para uso doméstico).

¿Qué podría causar una disminución en la concentración de oxígeno en un concentrador de oxígeno? (Respuesta: Filtros obstruidos, tamices moleculares envejecidos, falla del compresor).

¿Por qué el oxígeno del agua electrolizada no es adecuado para uso doméstico? (Respuesta: Consume electricidad, produce hidrógeno, presenta riesgos de seguridad y es costoso).

IX. Página final

Con esto concluye nuestra explicación sobre el funcionamiento del concentrador de oxígeno RespirEasy. Gracias por su atención y apoyo, y gracias al equipo de RespirEasy por su ayuda para recopilar esta información.

Teléfono: +86 18902540866

Correo electrónico: soporte@airoxygenconcentrator.com

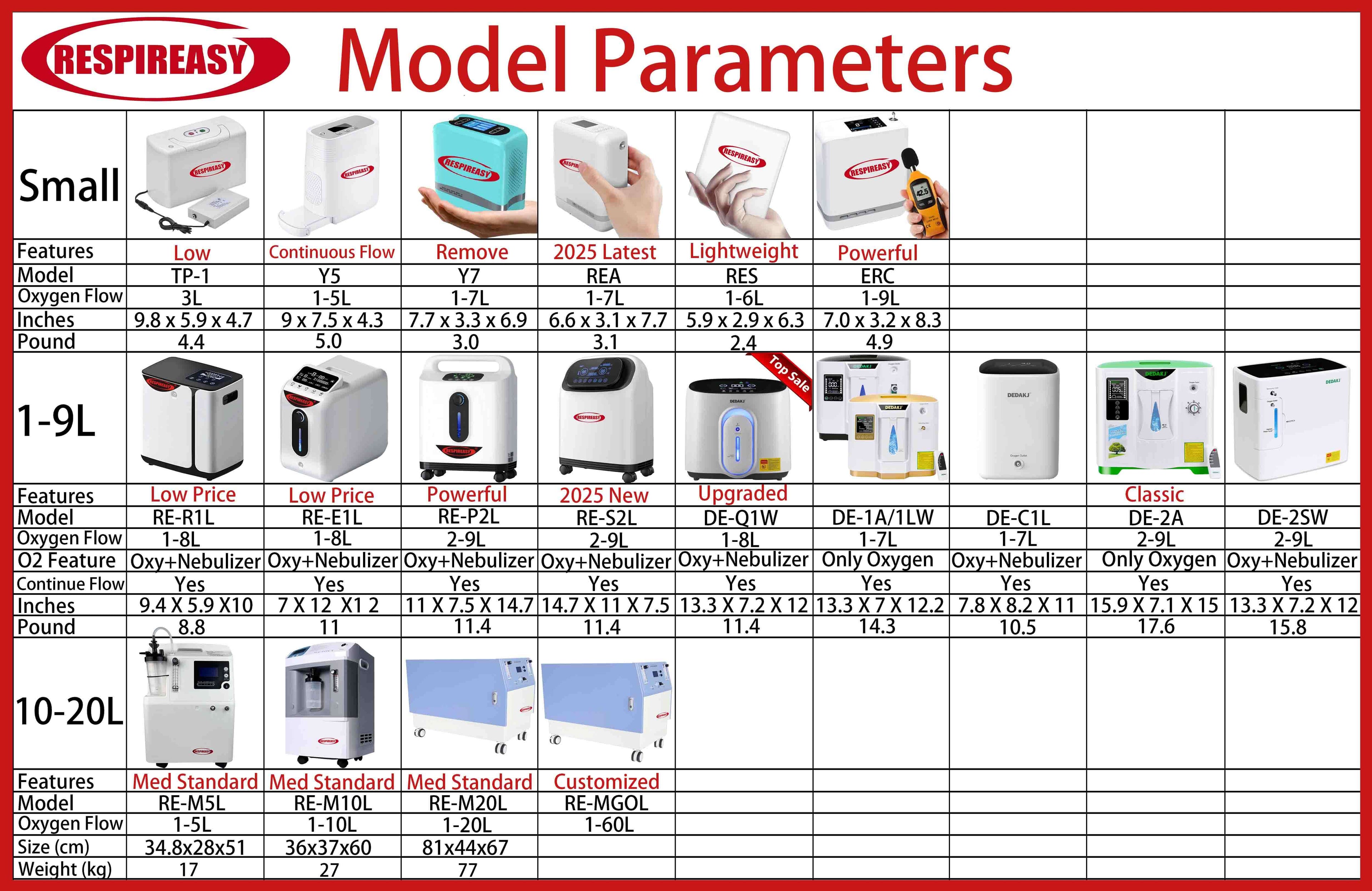

Acerca de RespirEasy-DEDAKJ

Proveedor de concentradores de oxígeno mejor valorado

DEDAKJ- RespirEasy Es un fabricante profesional de concentradores de oxígeno y ha estado profundamente involucrado en la producción de concentradores de oxígeno y máquinas para fabricar O2 durante más de 15 años.

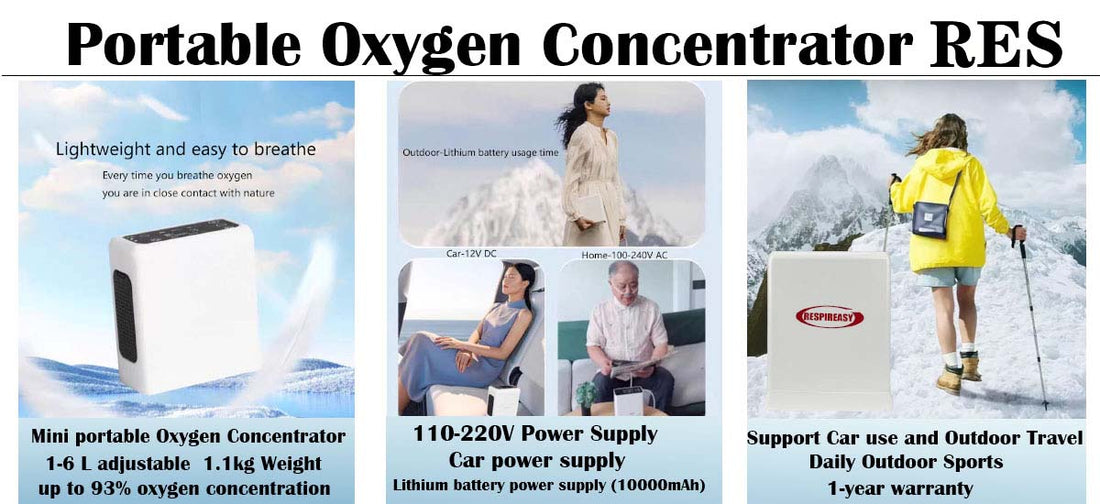

Los concentradores de oxígeno de uso doméstico de 1 a 9 LPM , Potente generador de O2 de 10 a 20 LPM . Generadores de oxígeno portátiles de tamaño mini de 1,2 kg . Filtro de oxígeno original dedakj, tanque de agua del humidificador, accesorios de control remoto para dedakj.